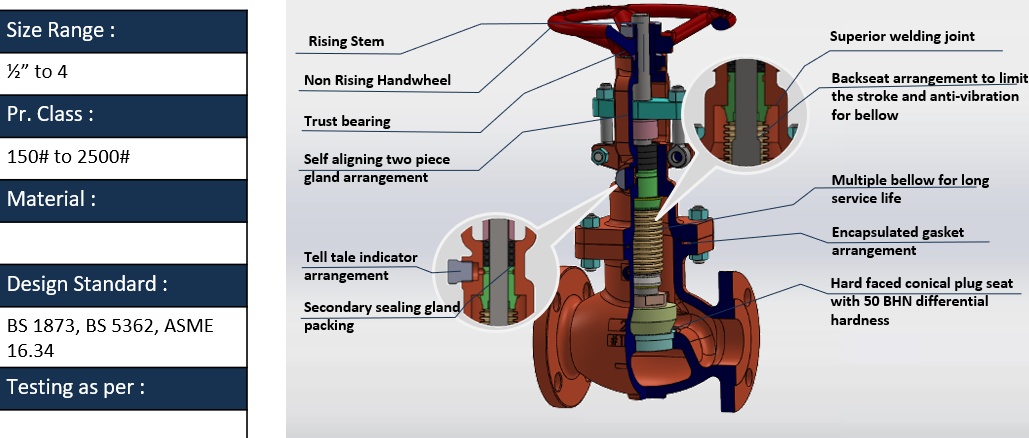

Bellow Sealed Instrumentation Valves

Our bellow sealed globe valve have been designed to meet your current and evolving instrumentation needs

Bellow sealed globe valve ensures a leak-tight seal around the valve stem thus reducing downtime for maintenance, and potential expenses associated with environmental protection

These valves can withstand extremely high temperatures and pressures or rapidly changing temperatures with a huge delta due to its bellow sealed design

They can be operated manually or be automated with various types of actuators

Our bellow sealed globe valve design aims to satisfy all the plant’s requirements, ensure environmental safety and provide the best possible lifetime value.

Design Features

Optimal maintenance and cost of ownership:

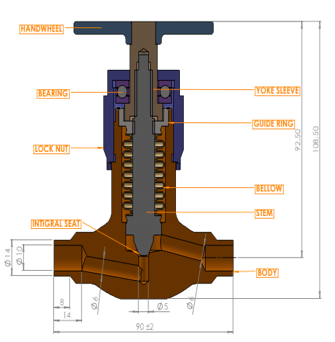

Single piece rising stem with outside roll-formed thread reduces the possible points of failure and enhances the service life

The guide ring prevents rotational movement of the rising stem and safe guards the bellow from torsional effects.

The stopper pin (stem head) control the valve open position and also act as anti- vibration device of stem.

The bellow carries a maintenance-free guarantee of 5,000 cycles; higher cycle life of 10,000 cycles available on request.

Very low potential for inner parts wear :

No “soft” materials (e.g. PTFE, sealing rings) are used. All internals are made of metal. (Note: Soft seat is available as an option). Very small interface between plug and seat (called a knife-edge seating system) limits wear.

The Conical shaped seating surface reduces the possibility of trapping sediments

The plug (integral with stem) and the integral body seat surface is hard-faced (Stellited) to ensure long lasting sealing

Leakage prevention and environmentally safe design:

The single piece body construction with especially built with high quality materials and construction methods of bellows is fully welded into the valve prevents the leakage around the stem and body seal area.

The lapped small “target “surface between plug and seat, ensuring bubble tightness with low closure torque.

The superior valve design minimizes the emissions into the environment and the need for frequent maintenance over the valve’s lifetime